AZZU’BI has established itself as a leader in the metal casting industry, renowned for its innovative solutions and commitment to quality. They have successfully executed numerous projects that not only meet but exceed client expectations. This case study delves into some of their most successful projects, highlighting the strategic approaches and techniques that have contributed to their success.

Project Overview: Automotive Components

Project Overview: Automotive ComponentsOne of the standout projects by AZZU’BI involved the production of high-precision automotive components. The company collaborated with a leading automobile manufacturer to deliver parts that were both lightweight and durable. The project required meticulous attention to detail and adherence to stringent industry standards.

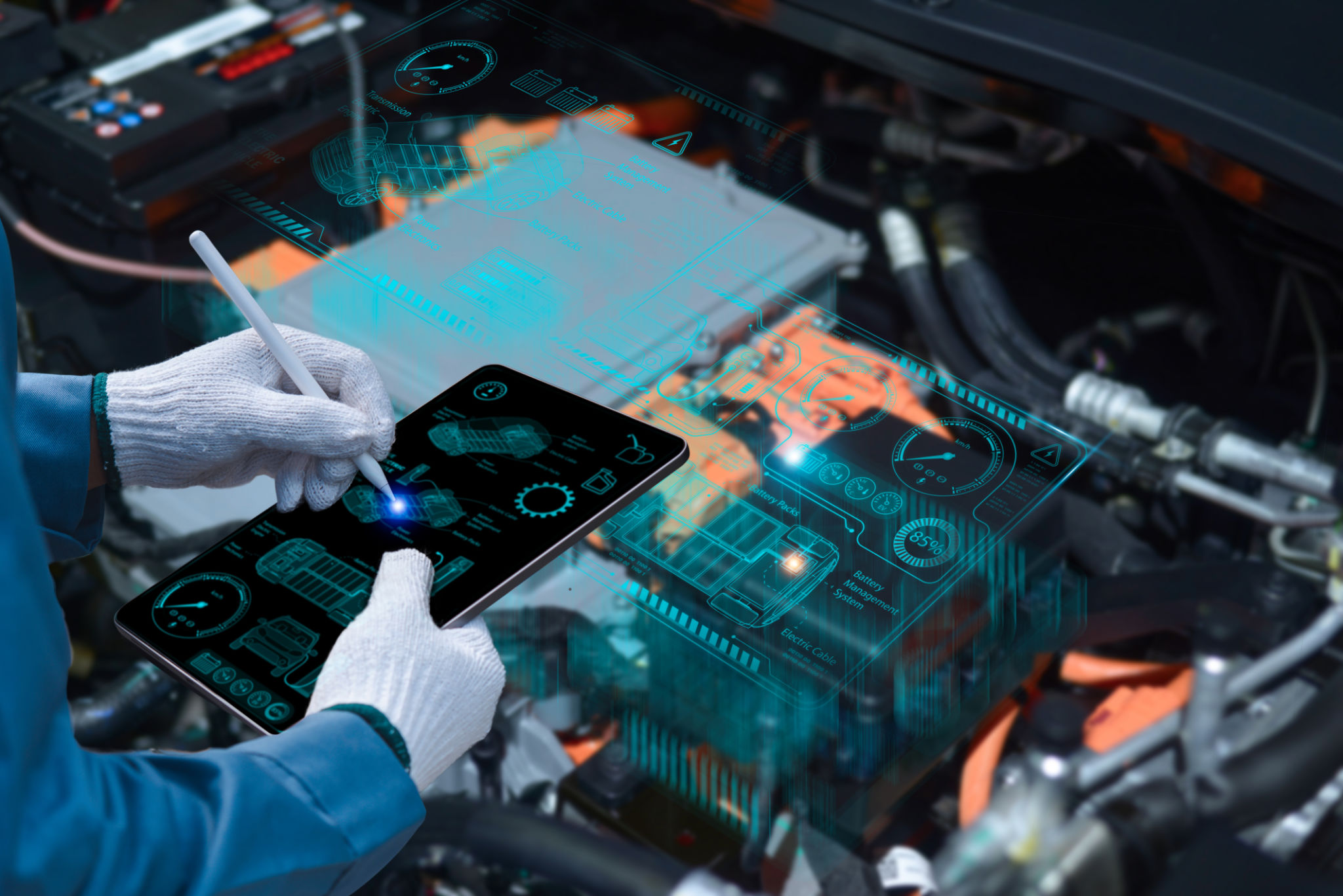

The team at AZZU’BI implemented advanced casting techniques to ensure each component met the required specifications. By using innovative alloys and refining their casting processes, they were able to enhance the performance of the automotive parts, contributing to improved vehicle efficiency.

Challenges and SolutionsThe primary challenge was achieving the perfect balance between weight and strength. AZZU’BI addressed this by conducting extensive research and development, experimenting with different material compositions. This iterative process allowed them to develop a solution that met all client requirements.

Project Success: Architectural Castings

Project Success: Architectural CastingsAnother significant project highlighted AZZU’BI's expertise in architectural castings. Working with architects and construction firms, AZZU’BI produced intricate metal designs for a landmark building. The project showcased the company’s ability to blend functionality with aesthetic appeal.

The intricate designs required precision and creativity. AZZU’BI utilized state-of-the-art 3D modeling software and cutting-edge casting technology to bring the architects' vision to life. This project not only enhanced the building’s visual appeal but also demonstrated the versatility of metal casting in modern architecture.

Client Feedback and OutcomeThe clients were highly impressed with the results, noting the durability and artistic quality of the castings. This project solidified AZZU’BI's reputation as a go-to partner for complex architectural projects, opening doors to new opportunities in the industry.

Innovations and Technologies

Innovations and TechnologiesAZZU’BI's success can largely be attributed to its commitment to innovation. The company continually invests in new technologies and processes to stay ahead of industry trends. Their use of computer-aided design (CAD) systems and automated casting techniques has set them apart in a competitive market.

Additionally, AZZU’BI’s focus on sustainability is noteworthy. They have implemented eco-friendly practices throughout their operations, from using recycled materials to minimizing waste during production. This commitment not only benefits the environment but also appeals to clients seeking sustainable solutions.

Future ProspectsLooking ahead, AZZU’BI plans to expand its capabilities even further. With a focus on research and development, they aim to explore new alloys and casting methods that can revolutionize various industries. Their proactive approach ensures they remain at the forefront of metal casting innovation.

Copyright 2026 © GEEL TECH . All Right Reserved

Share This News