Seasonal Maintenance Tips for Metal Cast Products

Understanding the Importance of Seasonal Maintenance

Metal cast products are renowned for their durability and strength, but like any material, they require regular maintenance to ensure longevity and performance. As the seasons change, different environmental factors can affect metal cast products. Performing seasonal maintenance helps in preserving their integrity and appearance.

Each season brings its own set of challenges. From the corrosive nature of winter salting to the high humidity of summer, understanding these challenges can help you take preventive measures. Keeping a regular maintenance schedule not only prolongs the life of metal cast products but also enhances their visual appeal.

Spring: Preparing for the Thaw

As winter recedes and temperatures start to rise, spring is the perfect time to inspect your metal cast products for any damage caused by snow and ice. Begin by thoroughly cleaning the surfaces to remove any residual salt or debris. This helps in preventing corrosion and rust formation.

Check for any visible signs of rust or wear and address them immediately. Use a wire brush or sandpaper to remove rust spots, followed by applying a rust-inhibiting primer and paint. This will provide an additional layer of protection against spring rains and humidity.

Summer: Combatting Heat and Humidity

During the summer months, metal cast products can be affected by high temperatures and increased humidity levels. To mitigate these effects, ensure that all metal surfaces are adequately coated with a protective finish. This finish acts as a barrier against moisture and UV rays.

Regularly inspect for any signs of blistering or peeling paint. Address these issues promptly by sanding down affected areas and reapplying a protective coating. Keeping metal cast products shaded or covered when not in use can also help reduce exposure to harsh sunlight.

Autumn: Preparing for Cooler Temperatures

Autumn is a critical time for maintenance as it prepares metal cast products for the upcoming winter months. Begin by clearing any fallen leaves or debris from around the products. Moisture trapped under leaves can accelerate corrosion.

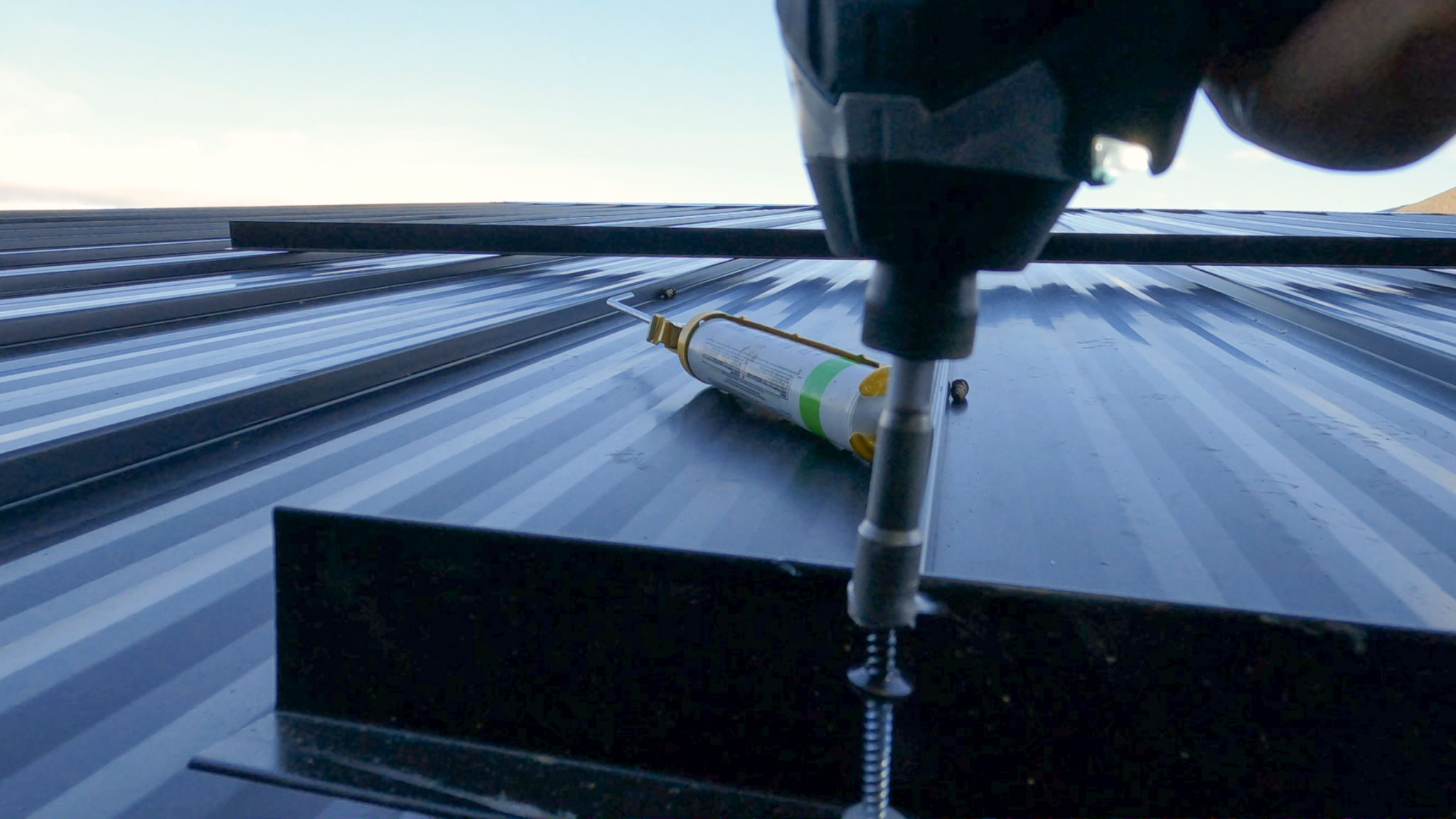

Inspect joints, hinges, and fasteners for any signs of wear or loosening. Tighten and lubricate these areas to ensure smooth operation during colder months. A thorough inspection now can prevent small issues from becoming significant problems in winter.

Winter: Protecting Against Ice and Salt

Winter can be the most challenging season for metal cast products due to snow, ice, and road salt. To protect against these elements, regularly clear snow accumulation to prevent prolonged exposure to moisture. If your products are exposed to road salt, rinse them with fresh water periodically to reduce corrosive effects.

Consider using weatherproof covers during extreme conditions. These covers can provide an extra layer of protection against ice formation and salt exposure, ensuring that your metal cast products remain in optimal condition throughout the winter.

Conclusion: Regular Maintenance is Key

In conclusion, seasonal maintenance is crucial for preserving the longevity and functionality of metal cast products. By adhering to a consistent maintenance routine tailored to each season's specific challenges, you can significantly reduce wear and prevent costly repairs.

Remember that small efforts in cleaning, inspecting, and protecting your metal cast products can yield substantial benefits over time. By investing in regular maintenance, you're safeguarding your investment and ensuring that these products continue to serve you well for years to come.