How to Maintain Metal Cast Products for Longevity

Understanding Metal Cast Products

Metal cast products are widely used across various industries due to their durability and versatility. From automotive parts to household items, these products are essential in our daily lives. However, like any other material, they require proper maintenance to ensure longevity and optimal performance.

Understanding the type of metal used in the casting process is crucial, as different metals have unique properties and maintenance needs. Common metals used in casting include aluminum, iron, and steel, each requiring specific care.

Regular Cleaning and Inspection

Regular cleaning is the first step in maintaining metal cast products. Dust and debris can accumulate on the surface and lead to corrosion if not addressed. Use a soft cloth or brush to clean the metal surface gently. For stubborn grime, mild soapy water can be effective.

In addition to cleaning, regular inspections are essential. Look for signs of wear, such as cracks or discoloration. Early detection of these issues can prevent further damage and ensure the long-term integrity of the product.

Use Appropriate Cleaning Agents

While cleaning, it's important to use appropriate cleaning agents suitable for the specific type of metal. Avoid using harsh chemicals that could damage the metal's surface or finish. For instance, aluminum can be cleaned with a mixture of vinegar and water for a gentle yet effective solution.

Preventing Corrosion

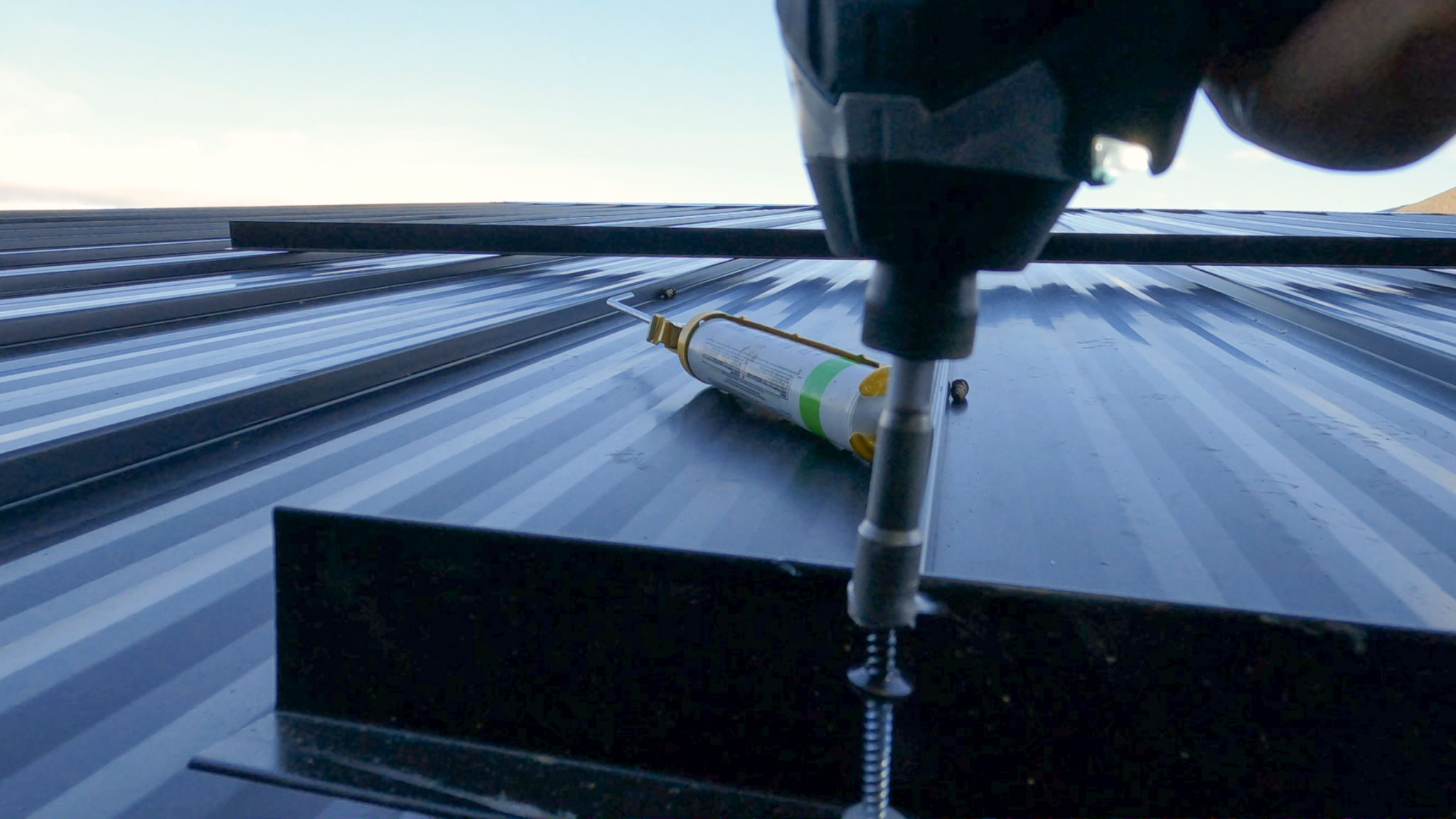

Corrosion is one of the biggest threats to metal cast products. To prevent it, ensure that the products are kept dry and stored in a moisture-free environment when not in use. Applying a protective coating or sealant can also provide an extra layer of protection against moisture and environmental elements.

For outdoor metal cast products, consider using weather-resistant paints or coatings designed to withstand the elements. These coatings not only enhance the appearance but also significantly extend the lifespan of the product.

Regular Lubrication

For moving metal parts, regular lubrication is vital to prevent wear and tear. Use lubricants that are compatible with the specific type of metal to ensure smooth operation and reduce friction. This practice not only enhances functionality but also prolongs the life of the product.

Proper Storage Solutions

When not in use, storing metal cast products correctly is crucial for their longevity. Avoid stacking heavy items on top of each other to prevent deformation or damage. Use padded storage areas to minimize scratches and other surface damage.

If possible, store metal items in a controlled environment where temperature and humidity levels are monitored. Extreme temperatures can cause metal to expand and contract, leading to potential cracking or warping over time.

Scheduled Maintenance

Implementing a scheduled maintenance routine can help identify potential issues before they become significant problems. Create a checklist that includes cleaning, lubrication, inspection, and any necessary repairs. Regular maintenance not only preserves the product's condition but also ensures it remains safe and functional for years to come.

By implementing these maintenance practices, you can significantly extend the lifespan of your metal cast products, ensuring they remain functional and aesthetically pleasing for years to come.