Case Study: Successful Metal Casting Projects by AZZU’BI Metal Casting

Introduction to AZZU’BI Metal Casting

AZZU’BI Metal Casting has established itself as a leader in the metal casting industry, renowned for its innovative techniques and commitment to quality. With years of experience, the company has successfully executed numerous projects across various sectors, including automotive, construction, and aerospace.

Understanding the Metal Casting Process

Metal casting is a complex process that involves pouring molten metal into a mold to create a desired shape. AZZU’BI excels in this craft, utilizing state-of-the-art technology and skilled craftsmanship to ensure precision and durability in every project.

The company offers a range of casting techniques such as sand casting, die casting, and investment casting. Each method is carefully selected based on the project requirements to achieve optimal results.

Project Highlight: Automotive Component Casting

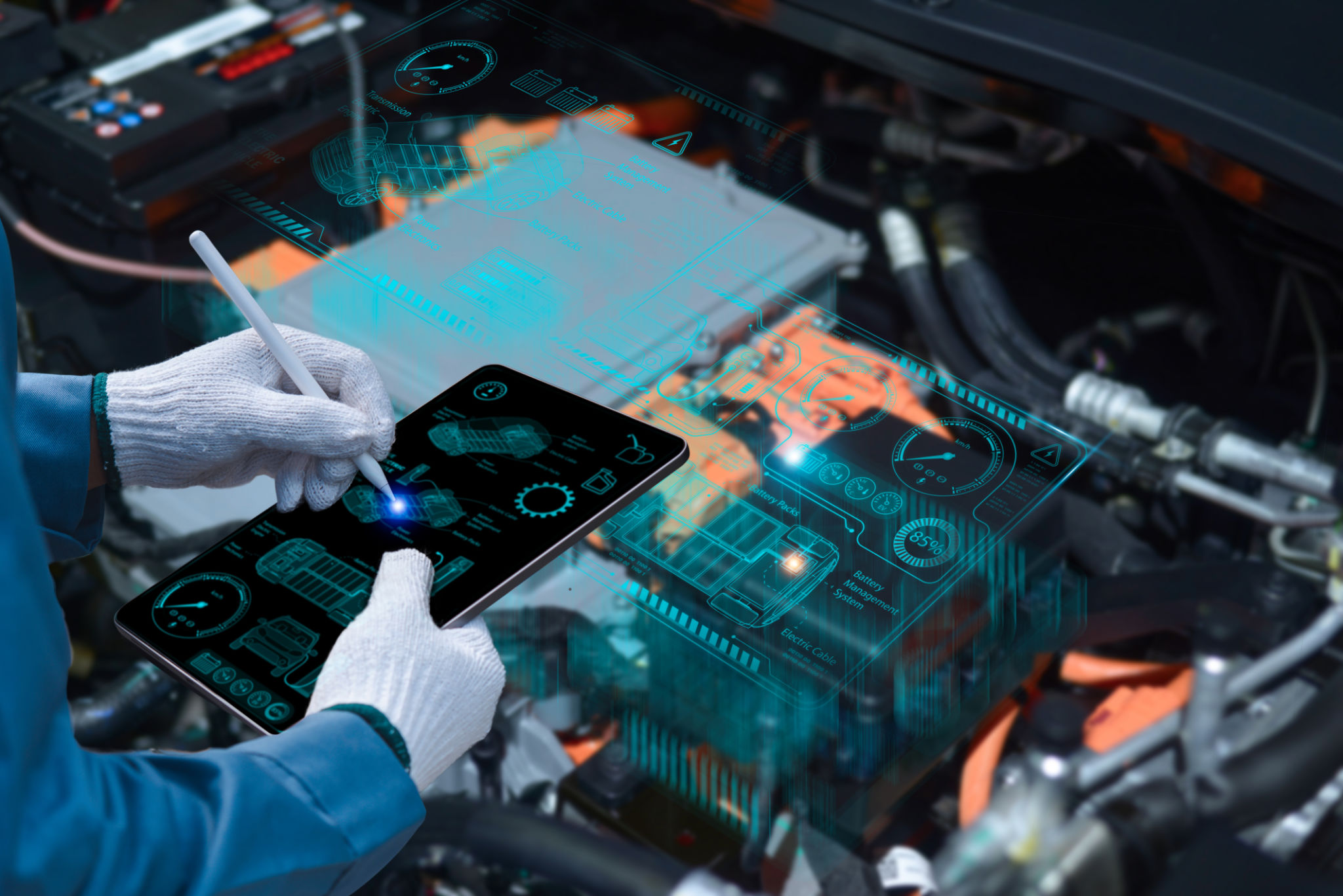

One of AZZU’BI's standout projects was the casting of lightweight aluminum components for a leading automotive manufacturer. The challenge was to produce parts that met stringent weight and strength criteria while maintaining cost efficiency.

AZZU’BI's team collaborated closely with engineers to refine the design and production process. The result was a series of components that not only met but exceeded industry standards for performance and durability.

Innovative Solutions in Construction

In the construction industry, AZZU’BI has been instrumental in creating custom metal castings for architectural projects. A notable achievement was the production of intricate façade elements for a landmark building.

The project required precision and creativity, and AZZU’BI delivered by utilizing advanced mold-making technologies and high-quality alloys. The outcome was a stunning architectural feature that showcased both artistic flair and engineering excellence.

Aerospace Advancements

AZZU’BI has also made significant strides in the aerospace sector, providing critical components known for their reliability and precision. Working on projects that demand exceptional tolerances and material integrity, the company demonstrated its capability to meet the rigorous standards of aerospace applications.

Their approach integrates thorough testing and quality assurance practices, ensuring each component can withstand the extreme conditions of aerospace environments.

Commitment to Sustainability

Beyond technical achievements, AZZU’BI is dedicated to sustainable practices in metal casting. The company continually invests in eco-friendly technologies and methods to reduce environmental impact.

By implementing recycling programs and optimizing energy usage, AZZU’BI not only enhances its operational efficiency but also contributes positively to environmental conservation efforts.

Conclusion

The successful projects by AZZU’BI Metal Casting highlight their expertise and leadership in the metal casting industry. From automotive to aerospace, their commitment to quality, innovation, and sustainability sets them apart as a trusted partner in metal casting solutions.

As they continue to push the boundaries of what is possible in metal casting, AZZU’BI remains at the forefront, ready to tackle future challenges with ingenuity and precision.